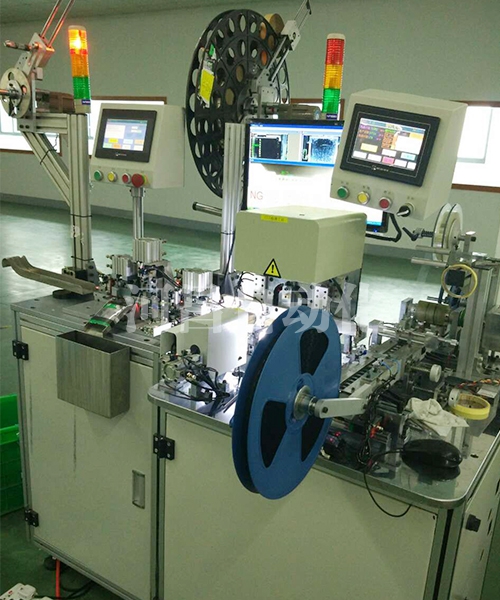

Industrial production is slowly adopting robots instead of manual production. It is widely used in industrial enterprises. From assembly, testing, handling to automatic welding, automatic spraying, automatic stamping, there are corresponding robots instead of manual reduction of staff. Labor force. When encountering a malfunction in daily use, the robot maintenance precautions must be followed before or during the maintenance of the robot arm to avoid danger. The following non-standard automation equipment manufacturers for everyone to introduce:

First, the robot maintenance notes:

1. Do not turn on the power or connect the air pressure to the robot, whether it is maintenance or maintenance;

2. Never use power tools in wet or rainy places and keep the work area well lit;

3. During the adjustment or replacement of the mold, please pay attention to safety to avoid being injured by the robot;

4, the mechanical arm rises/falls, introduces/retracts, traverses and unscrews the screws of the fixed parts of the knife, whether the nut is loose;

5. The baffle for the up and down stroke and the introduction of the stroke adjustment, whether the fixing screws of the anti-dropper bracket are loose;

6. Does the trachea not twist, and whether there is air leakage in each tracheal joint and trachea;

7, in addition to the proximity switch, suction clamp failure, solenoid valve failure can be repaired, other should be trained by professional training personnel, otherwise do not arbitrarily change;

Second, the robot maintenance tools summary

1. Hex wrench 2.5-8mm

2. Adjustable wrench 8-14mm

3. Cross screwdriver and slotted screwdriver

4. Diagonal pliers and needle-nosed pliers

5. Three-meter electric meter

6. Air spray gun

7. Oil gun

Suzhou Hechang Automation Technology Co., Ltd. is located in Chengdong Qingfeng Industrial Park, Wuzhi District, Wuzhong District, Suzhou. It is a professional non-standard automated processing assembly equipment and precision measuring equipment. Mainly cooperate with customers in the product processing industry automation equipment, product assembly, test automation equipment, testing (size, appearance) automation equipment, special inspection and fixture tooling and other aspects of customized development and manufacturing. Service Hotline: 86-512-66196533 Website: k2571.cn

86-512-66196533

Address: Chengdong Qingfeng Industrial Park, Wuzhi Town, Wuzhong District, Suzhou

Phone: 151-1912-8-8508

Website: k2571.cn